Guide to Sheet Materials

Sheet materials are extremely versatile and are used in almost all forms of construction.

They are also quite varied, with each having different properties that suit them for specific purposes.

This is a breakdown of the main sheet materials so that you may choose the right one for you.

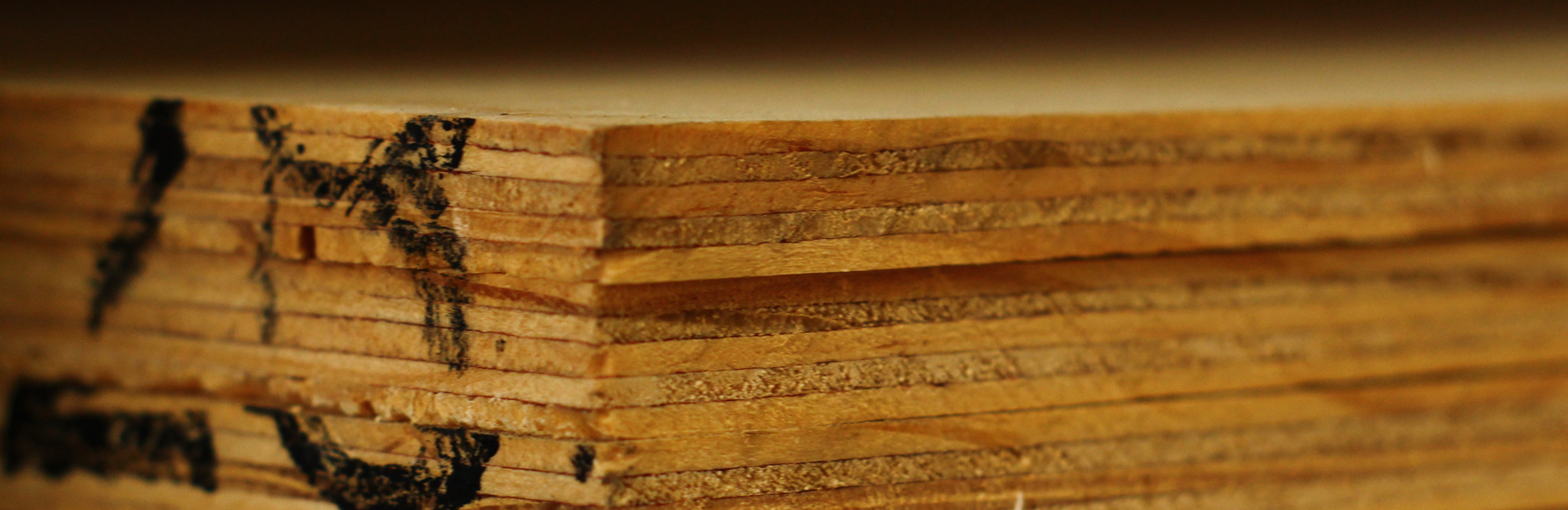

Plywood

Perhaps the best known sheet material derived from wood, bar perhaps paper,

plywood has some outstanding qualities that justify its 200 years of popularity.

An engineered timber, it is made from thin layer of wood veneer, also known as “plies” that are lain on top of one another.

Each layer is rotated by up to 90 degrees, this keeps the grains crossed to ensure strength.

This strength also keeps warping to a minimum and decreases the chance of splitting when nailed, tacked or screwed;

making plywood an extremely versatile construction material.

The main disadvantage of plywood also happens to be one of its strengths.

The layers that provide rigidity have the added downside of allowing water in that compromises the material

Over the years, plywood has been developed to better suit certain tasks.

Marine plywood for example has been modified to better withstand moisture, making it ideal for boats and situations where water exposure is likely.

Another form is veneered plywood, as its name suggests, this has been given a decorative veneer layer to make it more visually appealing.

As an opposite of veneered plywood, there is shuttering plywood.

This is engineered to be functional but not very pretty, it is denser and used for heavy duty construction purposes.

Blockboard

If plywood is too heavy for what you need then blockboard may be the perfect replacement.

Instead of having layers of veneer, blockboard consists of a core made from softwood strips,

or blocks, these strips are positioned edge to edge and are sandwiched between two veneers of hardwood.

This is then all glued together under pressure.

The weight and general qualities of blockboard are dependent on the core, though it is usually a light softwood.

It is best used inside and has a pretty good resistance to warping, meaning it is good for doors, furniture and shelves.

One of the down sides to blockboard is that it is not as strong as other sheet materials like plywood,

this is due to the centre being made from one layer of softwood blocks.

It is also possible for the blocks to separate when nails or screws are driven into the material at points where the blocks meet.

This can lead to internal voids and weakens the material overall. Though, if nails are inserted at the correct points, it holds them exceptionally well.

Chipboard

Chipboard, also known as particle board, or low density fibreboard (LDF) is another board with multiple advantages despite its low cost.

Chipboard has a very smooth texture on the sides thanks to it being made from compressed fibres and resin.

The edges are generally rough and require a veneer for an appealing finish.

A surprising property of chipboard is how it reacts to sound,

as it provides thermo-acoustic insulation, it is a favoured choice for the inside of speakers.

Frequently used in assembly furniture and kitchen worktops for its cost effectiveness,

chipboard is also more environmentally friendly than solid wood as the fibre used in its manufacture is usually recycled.

The issue with chipboard is that it is not very dense, so although it is light,

it is susceptible to transportation damage and is not ideal for load bearing purposes.

It is also not very good with moisture which easily causes damage.

So in summary, it is nice and affordable, but is not suited for the heavy duty stuff or dancing in the rain.

MDF

Much like chipboard, medium-density fibreboard (MDF) is a low-cost sheet material that is great at many things, but doesn’t do well in water.

Made from broken down wood residuals that have been mixed with resin and formed into a panel under pressure,

MDF is denser than plywood and lacks gaps and voids, unlike its close cousin, chipboard.

It has a very smooth surface and its consistency means it gives very neat lines when cut or routed.

The big downside hear is once again moisture;

without an uncompromising seal, it will deteriorate in water like a digestive in a cuppa.

Hardboard

Coming after LDF and MDF, we have HDF.

High-density fibreboard, also known as hardboard is much like MDF, yet is denser still.

It is made from compressed wood pulp that has been exploded and given

steam and heat treatments for a very fine finish that is tough, yet absorbent.

Hardboard can have either two smooth sides, or one smooth side and one rough fuzzy side, depending on what it is required for.

Whatever it is being used for, like most other board materials, if you don’t like the look you can apply a veneer to it.

As hardboard is denser still than MDF, it holds its form better and can be bought in thinner sheets.

Unfortunately for hardboard, it shares the same weakness as its low and medium counterparts, moisture again.

Though this can be overcome to an extent with tempering and oil treatments.

Cement board (AKA Tacboard, or Resistant Board)

The first board on this list that is not made from re-constituted wood fibre,

cement board, surprisingly enough, has cement in it.

The material is actually made from cement, fibres and sand which make it very heavy.

As it does not have a wood or wood fibre base, it is impervious to insects and rot decay.

It is also resistant to moisture, impact and extreme temperatures; this is really tough stuff.

The biggest down side here is that cement board, also known as fibre cement,

can be awkward to install due to its weight. More weight means more manpower, driving up costs and possibly time requirements too.

OSB Board

Going back to timber based materials for the final entry on this list, we have oriented strand board (OSB).

OSB, also known as flakeboard, sterling board or aspenite,

is made from compressed layers of wood strands (aka flakes) that are placed at specific angles to maximise its strength and load bearing capacities.

The angles of these strands give the board an axis of greatest strength, almost like a grain,

and because it is basically thousands of wooden flakes rammed together, it can be manufactured in massive sheets.

This process is more cost effective than making boards like plywood, so flakeboard is much cheaper.

OSB can be given special treatments to increase water resistance,

but you should know that the edges are prone to absorb water and weaken it.

For decorating, OSB provides a unique rustic look. It can be awkward to paint,

but with a primer and good oil-based paints, that hurdle is easily overcome.

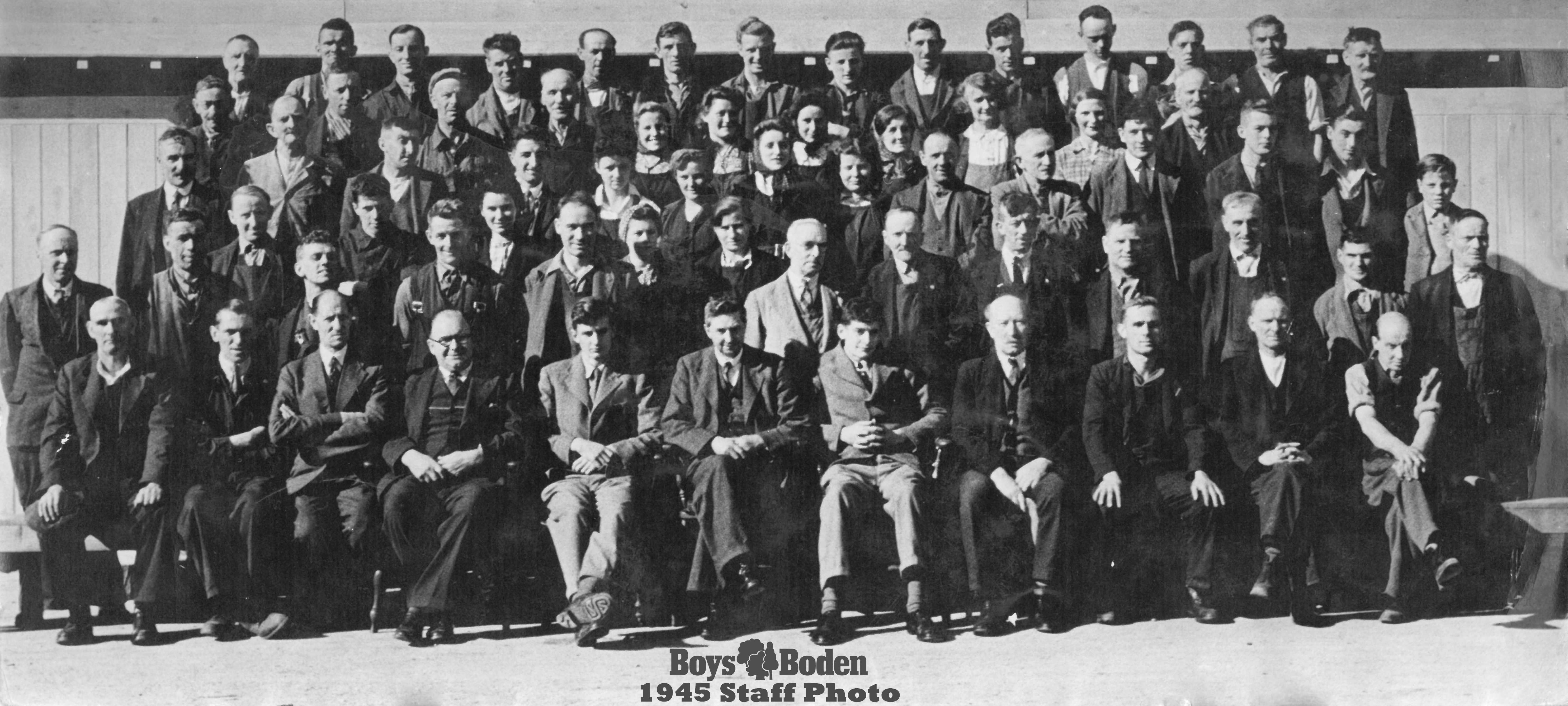

For more ideas and advice on materials, take a look at the wide product selection offered by Boys & Boden.

Or visit one of their branches, have a wander around and speak with their helpful staff.